For many years, people were afraid of fats, and some still avoid them. It was believed that if they were overweight, they were to blame. And many people of the older generation probably still remember about fears of cholesterol. From the article you can find out what fats (lipids) are, what they are, how much you should consume, and much more. Only verified information for you.

Application of fats

Fats improve the taste of food and cause a long-lasting feeling of fullness because they are digested and absorbed more slowly than other nutrients. The amount of fat in the diet is determined by various circumstances, which include labor intensity, climatic conditions, and a person’s age. A person engaged in intense physical labor needs more high-calorie food, and therefore more fat. https://depils.com/reports that the climatic conditions of the north, which require a large expenditure of thermal energy, also cause an increase in the need for fats. The more energy the body uses, the more fat is needed to replenish it.

Fats contain:

In addition to their high calorie content, the biological value of fats is determined by the presence of fat-soluble vitamins (A, D, E) and polyunsaturated fatty acids. Fats (or lipids) are synthesized by absolutely all living organisms and consist of “small” elements - fatty acid residues.

Based on the saturation of fatty acids with hydrogen atoms, they are divided into two large groups:

- Saturated fats

- Unsaturated fats

The most nutritionally valuable are unsaturated fatty acids. Some of them are not synthesized in the human body and are therefore essential. Vegetable fats mainly consist of unsaturated fatty acids. They are absorbed faster by the body and bring much more benefits than animal fats.

Polyunsaturated fatty acids - linoleic and arachidonic - are essential, since their synthesis in the body is extremely limited. They play an important role in metabolism: their lack in nutrition negatively affects the functioning of the human body. Linoleic acid makes up up to 50% or more of all fatty acids contained in vegetable oils.

Types of fats

There are saturated and unsaturated fats (fatty acids).

Saturated fats

They are solid at room temperature (except coconut and palm oils). The main source is animal products:

- red meat (pork, beef, etc.) and lard;

- dairy products (especially cheeses and butter);

Some vegetable oils:

- coconut and palm.

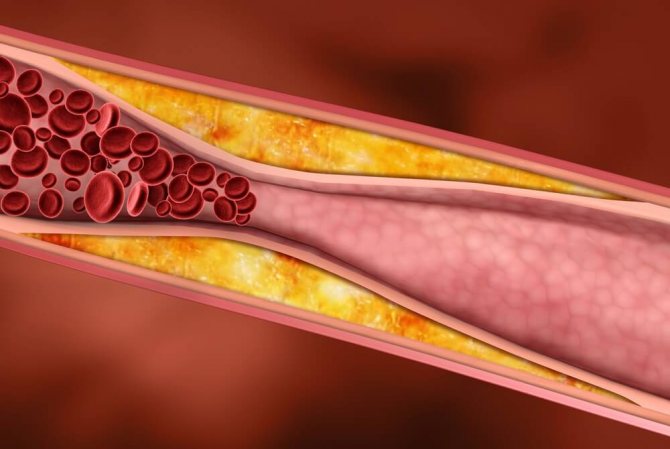

Saturated fats increase the risk of cholesterol deposits in the walls of blood vessels. At the same time, they provide the body with energy . The main thing is not to abuse it. Everything needs moderation.

The human body can synthesize saturated fatty acids on its own.

Trans fats

Trans fats are a type of unsaturated fat. We define them in a separate group, because they are obtained by hydrogenation of cheap vegetable oils . During complex chemical reactions, unsaturated fats become saturated.

These oils hold their shape well and provide a pleasant taste; baked goods with trans fats are stored well and remain fresh for a long time. The saddest thing is that thanks to this hydrogenation, changes occur in the molecules of initially harmless vegetable fats, turning them into extremely dangerous ones .

Trans fats are often linked to diabetes, strokes, heart attacks and even cancer . WHO recommends limiting them to a minimum. In some European countries their use is completely prohibited or severely limited.

What foods contain trans fats:

- margarine, spreads, cooking oil;

- most baked goods (cookies, waffles, cakes, pastries, etc.);

- chips and crackers;

- frozen meals;

- chocolates, bars, almost all chocolates;

- many dairy products;

- some sausages;

- all fast food.

The list may be incomplete, because manufacturers add hydrogenated oils everywhere and carefully hide it.

Almost 50% of foods sold in supermarkets contain trans fats.

Why not replace trans fats with something healthier?

The fact is that they are very cheap, and it is not possible to replace them without a significant increase in price in any country in the world. However, some countries are finding a solution for themselves.

In addition, trans fats are formed during frying as a result of prolonged high heating of vegetable oils .

A certain amount of trans fats is also found in common foods - meat and milk. However, their content in such products is so insignificant that there is no need to limit yourself in milk and meat.

Doctors recommend consuming up to 7 g of trans fats per day . Therefore, it is advisable to exclude industrial sweets, fast food and some other products. Or at least carefully read the ingredients on the product label. They are hidden under the phrases: “Partially hydrogenated vegetable fat”, “vegetable oils”, etc.

Monounsaturated fats

This includes omega 9 fatty acids, the main of which is oleic acid. It is also partially synthesized in the human body.

Sources:

- Vegetable oils (olive, sunflower, soybean, rapeseed, sesame, walnut, flaxseed, etc.).

- Avocado.

- Nuts and seeds.

- Chicken, red meat.

Omega 9 has a beneficial effect on cardiovascular health and can increase “good” cholesterol . Although for this it is important to reduce the consumption of saturated fats and replace them with unsaturated ones.

Research is currently ongoing to determine the benefits of monounsaturated acids for human health. The benefits of oils have been proven for a long time, but the benefits of these acids contained in meat are still in doubt among scientists.

Polyunsaturated fats

This includes the most beneficial essential omega 3 and 6 fatty acids. They are not synthesized in the body and must be obtained from food.

Perform essential functions in the body. A number of biologically active substances are produced from them. Therefore, they are necessary for normal metabolism.

Sources:

- Fatty fish, seafood.

- Fish fat.

- Vegetable oils (olive, sunflower, corn, rapeseed and others).

- Nuts, seeds.

Remember which foods contain healthy fats .

Polyunsaturated fatty acids:

- reduce the risk of cardiovascular diseases (strokes, heart attacks, atherosclerosis, coronary heart disease), diabetes;

- lower “bad” cholesterol and increase “good” cholesterol;

- have antioxidant and anti-inflammatory effects.

A little about the complex

Essential fatty acids include linoleic and linolenic acids. Linoleic acid and arachidonic acid formed in our body from it belong to omega 6 fatty acids.

Linolenic acid and its metabolic products, eicosapentaenoic acid (EPA) and docosahexaenoic acid (DHA), are omega 3 fatty acids. Only small amounts of EPA and DHA can be formed from linolenic acid.

However, eicosapentaenoic acid and docosahexaenoic acid can be obtained by consuming fish or fish oil.

A deficiency of essential acids can lead to diseases of the cardiovascular system and premature aging.

Sources of Selected Fatty Acids

| Polyunsaturated fatty acids | Main food sources |

| ω-6 | |

| Linoleic | Vegetable oil, nuts, seeds |

| ω-3 | |

| Linolenic | Flaxseed oil, soybean oil, flax seeds, walnuts, broccoli, Brussels sprouts |

| Eicosapentaenoic, docosahexaenoic | Fish, fish oil |

Omega 3

Separately, I would like to talk about the benefits of omega-3, eicosapentaenoic and docosahexaenoic acids, which can only be obtained with fish and fish oil.

Proven to perform the following tasks:

- acts as a prevention of heart attacks and strokes;

- prevents arrhythmias, slows down the number of heart contractions;

- reduces heart failure;

- prevents thrombosis;

- used in the treatment of depression;

- reduces insulin resistance, thereby preventing diabetes and oncology;

- has an anti-inflammatory effect.

Which is better, fish or supplements?

Doctors recommend eating fish several times a week. The best source of Omega 3 is fatty sea fish that live in cold waters. Therefore, it is better to give preference to sardines, herring, salmon, tuna, mackerel, and capelin. There is much less of it in squid and white sea fish, such as cod.

If you are unwilling or unable to eat fish regularly, it is advisable to take fish oil or an Omega-3 supplement directly.

There are 3 supplements on the market:

- Fish oil , which is sold in pharmacies, usually contains both omega 3 and 6, as well as some vitamins. It should be used for vitamin deficiencies, or as a source of small amounts of essential fatty acids. Fish oil is most often prescribed to children.

- For adults, omega 3 or omega 3, 6, 9 . Moreover, omega - 3, 6, 9 is most often taken by athletes who completely exclude all fats from their diet. An ordinary person does not need such a supplement. Why?

Because the ratio of omega-3 to omega-6 in your diet is extremely important.

The optimal ratio of omega-3 to omega-6 should be, according to various sources, from 1:2 to 1:4. However, in the diet of most people the ratio is 1:20 or more towards omega - 6. After all, as you remember, omega - 6 is found in vegetable oils, nuts, seeds, avocados, etc. Every person consumes these to one degree or another products.

Excess omega 6 can lead to increased blood clotting, blood clots, heart attacks and strokes. It is recommended to add omega-3 to the diet and reduce omega-6.

Therefore, it is omega-3 fatty acids that enter your body and it is recommended to eat fish a couple of times a week. Or Omega-3 supplement in capsules.

Nowadays there is a huge selection of fish oil on sale, both in liquid form and in capsules. You need to be very serious about choosing a brand, because you need a high-quality drug.

I recommend paying attention to this premium Omega 3 at an affordable price . It is manufactured under strict quality control. This brand of fish oil is tested to be free of heavy metals, mercury, and other harmful substances.

Fat calories

The calorie content of animal and vegetable fats is approximately the same. Fats should account for about 30% of the calorie content of a person’s daily diet, i.e., daily dietary fat intake should be 90-100g. Taking into account the body's need for polyunsaturated fatty acids, 30% of the fat consumed should be vegetable oils and 70% animal fats.

Much attention is currently paid to the fat-like substances contained in fats - phospholipids, cholesterol and others, which are actively involved in various processes of the body. The requirement for phospholipids is about 5g. per day. They are found in significant quantities in fatty meats, egg yolks and other products. Cholesterol enters the body with products of animal origin and is also synthesized by it.

Fats should be used in quantities most favorable for replenishing energy expenditure.

It has been established that the daily fat requirement of an adult is satisfied by 75-110 g.

It should be noted, however, that the amount of fat in the diet is determined by various circumstances, which include labor intensity, climatic conditions, and a person’s age. A person engaged in intense physical labor needs more high-calorie food, and therefore more fat. https://depils.com/ The climatic conditions of the north, which require a large expenditure of thermal energy, also cause an increase in the need for fats. The more energy the body uses, the more fat is needed to replenish it.

Despite its importance in nutrition, fats are associated with many dietary restrictions due to the traditionally high fat content in many national diets. Currently, due to changes in living conditions and the quality of work, which increasingly requires mental expenditure and less physical, their large consumption only leads to health problems.

But we must not forget that excess fat, even in the diet of a healthy person, is harmful.

Fats do not dissolve either in water or digestive juices. In the body they are broken down and emulsified with the assistance of bile. Excessive fat does not have time to emulsify, disrupts digestive processes and causes the unpleasant sensation of heartburn.

A large amount of animal fat in food significantly impairs the absorption of proteins, calcium and magnesium, and increases the need for some vitamins involved in fat metabolism. It is from these disorders and limitations that various pathologies begin to form - for example, atherosclerosis, diabetes mellitus, gallstone disease. So it is better to limit the amount of fat in food, especially the amount of animal fat, and get energy from carbohydrates.

The role of fats in the body

Basic rules that must be followed to facilitate the body's absorption of fats.

1. The body does not absorb fats well from highly fatty foods: pork, chicken legs, cakes, pastries. Therefore, this food should not dominate the diet.

2. It is necessary to constantly maintain the functioning of the liver and gall bladder.

3. You should not wash down your food with water or other drinks. This habit, on the one hand, dilutes the digestive juice, and on the other hand, washes food into other parts of the intestine, where the breakdown of fats does not occur so effectively.

Our body needs fats not only to be deposited on the waist and hips. Fats are the most important nutrients, and when they are deficient in food, serious health problems arise.

1. Fats are necessary for the formation of cell membranes and connective tissue.

2. Adipose tissue is a support for internal organs (heart, liver, kidneys), and with excessive thinness, the organs are displaced and their activity is disrupted.

3. Components of fats (unsaturated fatty acids) help remove excess cholesterol from the body.

4. Fats increase the elasticity and permeability of the walls of blood vessels.

5. Fats contain fat-soluble vitamins A, E, D, which are essential for the body.

6. A lack of fat in the diet impairs the functioning of the heart muscle and negatively affects the condition of the skin.

7. Fats are involved in the synthesis of hormones - substances that the body constantly needs for normal functioning.

Fat is fat - discord, and not comrade.

This could be the end of the story about fats, but in real life not everything is so simple and smooth. Fats that enter the body with food may have different properties and may not fully perform the functions assigned to them by nature. The properties of fat depend, first of all, on what fatty acids are included in its composition. Varieties of modern edible fats.

1. Saturated fat - composed of glycerol and saturated fatty acids, it usually has a solid consistency even at room temperature. The source of saturated fats most often comes from animal products. These fats are harmful to the body when there is a lot of them in food - they contribute to increased cholesterol levels in the blood and the development of cardiovascular diseases. We must remember that saturated fats are not essential for humans and can be synthesized from other substances.

2. Unsaturated fats are found in vegetable oils, nuts and some types of sea fish. Unsaturated fats do not solidify at room temperature, even in a regular refrigerator. The best-known ingredients of unsaturated fats are Omega-3 and Omega-6 polyunsaturated fatty acids. Almost all the benefits that fats bring to the body can be attributed to unsaturated fatty acids. What is very important: unsaturated fatty acids are not synthesized by the body, and products containing them must be present in the human diet: marine fatty fish that live in the northern seas, nuts, canola oil, walnut oil, flaxseed oil.

3. Trans fats are the worst fat that is harmful to the body in any concentration. It is obtained after heating vegetable fats to high temperatures in the presence of hydrogen. Trans fats are widely used in semi-finished products, industrially produced sweets, fatty ketchups, and sauces.

As we can see, the key to health is a balanced attitude towards fatty foods: eliminate trans fats from your diet, minimize saturated fats and consume unsaturated fats in reasonable quantities.

Most of the fats we eat are used by our body or stored in reserve. Under normal conditions, only 5% of fats are excreted from our body, this is done with the help of the sebaceous and sweat glands.

Regulation of fat metabolism in the body occurs under the guidance of the central nervous system. Our emotions have a very strong influence on fat metabolism. Under the influence of various strong emotions, substances enter the bloodstream that activate or slow down fat metabolism in the body. For these reasons, one must eat in a calm state of consciousness.

Nutritional value of fats

The nutritional value of different fats is not the same and largely depends on the digestibility of fat by the body. The digestibility of fat, in turn, depends on its melting temperature. Thus, fats with a low melting point, not exceeding 370 (i.e., human body temperature), have the ability to emulsify most completely and quickly in the body and, therefore, are most fully and easily absorbed.

Fats with a high melting point are absorbed much less well. While butter is absorbed by the body up to 98.5%, lamb fat is absorbed only by 80-90%, beef fat, depending on its melting point, by 80-94%.

Fats with a low melting point include butter, lard, goose lard, all types of margarines, as well as liquid fats.

Fats with a high melting point are absorbed much less well. While butter is absorbed by the body up to 98.5%, lamb fat is absorbed only by 80-90%, beef fat, depending on its melting point, by 80-94%.

What are the benefits of fat?

The most important nutritional components of vegetable fat: mono- and polyunsaturated fatty acids, vitamins, phytosterols, phospholipids. Let's look at each element in more detail. Fat is the most concentrated source of energy. 80% of a person’s energy reserve is formed by fat, which is why it is vitally important to compensate for its deficiency and constantly introduce new fatty combinations into the diet. Polyunsaturated fatty acids are responsible for:

- formation of a strong structure of the cell membrane, its stability and high-quality functioning;

- acceleration of metabolic processes;

- removing “bad” cholesterol from the body;

- strengthening the walls of blood vessels, increasing their elasticity and reducing permeability.

Phytosterols help cope with bad cholesterol - reduce its concentration, speed up metabolism and remove it from the body. Phospholipids take part in fat metabolism, making it efficient and less energy-consuming. The component is responsible for the integrity and strength of cell membranes, promotes high-quality and rapid cell growth. Phospholipids are one of the building blocks of nervous tissue, brain and liver cells. The plant component is also responsible for reducing the level of formation of oxidation products in the blood.

Vegetable oils contain retinol, tocopherol and provitamin A. They have the following properties:

- protecting the body from radiation exposure;

- prevention of cancer development;

- activation of protein synthesis;

- protection against diabetes and a number of diseases of the cardiovascular system;

- increasing the degree of absorption of beneficial vitamins and nutrients.

A lack of vegetable fats in the body leads to serious health problems. Energy metabolism deteriorates and the level of immune defense decreases. The person feels apathetic, tired, and unable to perform routine duties. Lack of fat causes hormonal imbalance and can lead to irreversible consequences.

Fat in cooking

It is difficult to overestimate the importance of fats in cooking. One of the main culinary processes - frying - is usually carried out with the help of fats, since due to poor thermal conductivity, fat makes it possible to heat the product to high temperatures without burning or igniting. By forming a thin layer between the bottom of the pan and the product being fried, fat promotes more uniform heating.

Due to its ability to dissolve some coloring and aromatic substances extracted from vegetables, fat is also used to improve the appearance and smell of food. It is well known that the taste and nutritional value of food can be improved by adding various fats to it. When selecting fat for preparing a particular dish, the cook must take into account not only its digestibility by the body, which is especially important when preparing dietary and baby foods, but also how this fat reacts to strong heating.

Not all fats can be heated to high temperatures without decomposition, which is detected by the appearance of smoke. The temperature of smoke formation is different. Butter, for example, can only be heated to 2080. As the temperature rises, it decomposes and gives the fried product an unpleasant bitter taste.

Pork lard without decomposition can be heated to 2210, and kitchen margarine to 2300. Kitchen margarines, in addition, contain a small amount of moisture, which makes them very convenient for frying various foods.

Ghee also cannot withstand heating to high temperatures. You can use it for frying only when you do not need to heat the product very much and when the frying process proceeds quickly. The choice of fat also depends on its taste compatibility with the culinary product.

All chefs know very well that the taste of a food is determined not only by the main product, but also by the fat used for its preparation. Fat that does not suit the taste of a given dish can worsen it. You cannot, for example, cook sweet pancakes with jam using beef or pork lard, and if there were no other fats suitable for these pancakes, then it was impossible to cook them and include them in the menu.

Incorrect selection of fat for preparing a given dish is a violation of one of the basic laws of cooking, and only an inexperienced, inept cook uses fats that do not match their taste with the product.

Butter

The delicate, subtle taste of many dishes corresponds to the pleasant smell and soft taste of butter.

Butter is used primarily for sandwiches, as well as for topping a number of prepared foods, especially those prepared from dietary and deli products, as well as for seasoning sauces.

You should not use butter for frying, especially because this oil contains up to 16% moisture and therefore splashes a lot. In many cases, butter can be replaced by all types of table margarine.

Animal fats

Animal fats - beef and lard - are used for hot meat dishes and frying some types of flour products. Lamb lard is successfully used to prepare many dishes of Caucasian and Central Asian cuisine.

Liquid fats vegetable oils

Liquid fats - vegetable oils - are used in all cases where the recipe requires the use of non-solidifying fat.

The use of a particular fat for different foods is often determined by its melting point. Thus, refractory fats can also be used in dishes that are served only hot. For those foods that are served both hot and cold, refractory fats are not suitable, since when they solidify they give an unpleasant aftertaste, as they say, “get cold on the lips.” For these dishes, it is advisable to use vegetable and cow oil, margarine, and lard. Despite the fact that margarine and lard also become dense when they harden, they quickly melt in the mouth and do not give the food a “greasy” taste.

The importance of fats in human nutrition

The role of fats in the body

Fats

(

lipids

from the Greek lipos - fat) refer to the main nutrients (macronutrients). The importance of fat in nutrition is varied.

Fats in the body perform the following main functions:

energy —

are an important source of energy, superior in this regard to all nutrients.

When 1 g of fat is burned, 9 kcal (37.7 kJ) are formed;

plastic -

are a structural part of all cell membranes and tissues, including the nervous one;

are vitamin solvents

A, D, E, K and contribute to their absorption;

serve as suppliers of substances with high biological activity

: phosphatides (lecithin), polyunsaturated fatty acids (PUFAs), sterols, etc.;

protective -

the subcutaneous fat layer protects a person from cooling, and the fats around the internal organs protect them from shocks;

gustatory -

improve the taste of food;

cause a feeling of prolonged satiety

(feeling full).

Fats can be formed from carbohydrates and proteins, but are not fully replaced by them.

Fats are divided into neutral (triglycerides)

and

fat-like substances (lipoids).

Biological effectiveness of fats

Neutral fats

consist of

glycerol

and

fatty acids

.

Fatty acids largely determine the properties of fats.

Biological effectiveness

- an indicator of the quality of food fats, reflecting the content of essential polyunsaturated fatty acids in them.

More than 200 fatty acids have been found in nature, but only 20 are of practical importance.

Fatty acids are divided into saturated, monounsaturated, polyunsaturated

.

Saturated fatty acids

(saturated to the limit with hydrogen -

limiting

) - palmitic, stearic, myristic, oil, nylon, caprylic, arachidic, etc.

In high molecular weight

saturated fatty acids (stearic, arachidic, palmitic) have a solid consistency,

low molecular weight

(butyric, caproic, etc.) - liquid. (most vegetable oils).

Solid fats are dominated by saturated fatty acids (animal and poultry fats). The more saturated fatty acids, the higher the melting point of the fat, the longer it takes to digest and the worse it is absorbed (lamb and beef fats).

The biological activity of saturated fatty acids is low.

Saturated fatty acids are associated with ideas about their negative impact on fat metabolism and the development of atherosclerosis. There is evidence that an increase in cholesterol levels in the blood is associated with the intake of animal fats that contain saturated fatty acids. Excessive intake of solid fats also contributes to the development of coronary heart disease, obesity, cholelithiasis, etc.

Monounsaturated

(

monenoic)

- these include

oleic acid

, found in almost all fats of animal and vegetable origin.

A large amount of it is found in olive oil (66.9%). There is evidence of the beneficial effect of oleic acid on lipid metabolism, in particular on cholesterol metabolism and biliary tract function.

WHO (2002) classified oleic acid as a possible, but not definitively proven, nutritional factor that reduces the risk of cardiovascular diseases.

Polyunsaturated (polyene, PUFA

)

- having two or more free double bonds.

These include linoleic

acid having two double bonds,

linolenic acid

having three double bonds, and

arachidonic acid

having four double bonds.

These acids, due to their biological properties, are called vitamin

F. Linoleic and linolenic acids are considered essential nutrients, because

are not synthesized in the body and are supplied only with food.

PUFAs are involved in the regulation of metabolic processes in cell membranes and in the formation of energy in mitochondria. About 25% of the fatty acid composition of the membranes is arachidonic acid. Tissue hormone-like substances (prostaglandins) are formed from PUFAs in the body; they have a positive effect on fat metabolism in the liver, increase the elasticity of blood vessels, normalize the condition of the skin, and are necessary for the normal functioning of the brain.

PUFAs are able to bind cholesterol in the blood, form an insoluble complex with it and remove it from the body (anti-sclerotic role).

The transformation of PUFAs in the body depends on the chemical structure, namely the position of the first double bond from the methyl end. Yes, linoleic

acid, this bond is located in

position 6.

All other acids (in particular arachidonic acid) formed from it also have the first double bond in position 6 and belong to the

omega-6 family of PUFAs.

In linolenic

acids, the first free double bond is the most distant and is located in

position 3

, therefore this acid and the products of its transformation (eicosapentaenoic, docosapentaenoic and docosahexaenoic fatty acids) belong to

the omega-3 PUFA family.

Vegetable oils (sunflower, corn, cottonseed and soybean) are very rich in linoleic acid.

Good sources of linoleic acid are soft margarines, mayonnaise, and nuts. Of the cereals, it is most abundant in millet, but 25 times less than in sunflower oil.

Vegetable fats

Vegetable fats are extracted from the seeds of oilseed plants by pressing or extraction.

The essence of the pressing process is to squeeze oil out of crushed seeds, from which most of the hard shell (peel) has been previously removed. Depending on the method of conducting the technological process, cold-pressed and hot-pressed oil are distinguished. During hot pressing, crushed seeds are preheated in roasters. Extraction consists of a number of sequential operations: cleaning, drying, removing the shell and grinding the seeds, extracting oil from them using special solvents and then removing the solvent from the oil.

Vegetable oil is purified either by filtration or by exposure to alkalis. In the first case, the product is called unrefined, in the second, refined. The oil obtained by extraction is edible only in refined form.

Refined vegetable oil is most suitable for frying, since particles of mucous and protein substances remaining in unrefined oil when fat is heated to a high temperature quickly decompose and can give the fried product a bitter taste and a specific unpleasant (“smoky”) odor.

Some vegetable oils, in addition to refining with alkali, are subjected to bleaching and deodorization. Deodorization is achieved by reducing or completely eliminating the specific odor of the oil. Of the vegetable oils, the range of which is very wide and includes fats with different chemical and physical properties, the most commonly used in cooking are sunflower, cottonseed, olive, soybean, and peanut; flaxseed, hemp, and corn oils are less commonly used. In confectionery production, sesame and nut oils are used, and in baking, mustard oil is used.

Sunflower oil

Sunflower oil is obtained by pressing or extracting sunflower seeds. The oil, produced by pressing and especially hot, has an intense golden yellow color and a pronounced aroma of roasted seeds. Sunflower oil is sold refined and unrefined. Refined and deodorized oil is transparent and almost devoid of a specific odor.

According to its commercial qualities, unrefined sunflower oil is divided into three grades (highest, 1st and 2nd).

Dressings for salads, vinaigrettes, and herring are prepared using sunflower oil. It is used in cold appetizers, especially vegetable ones (squash, eggplant, mushroom caviar, stuffed peppers, eggplants, tomatoes). The same oil is used for frying fish, vegetables and some dough products. Refined and deodorized sunflower oil is most suitable for salad dressings, as well as for making mayonnaise.

Olive oil

Olive oil (Provençal oil) is extracted from the fleshy part of the olive tree and from the kernel of its hard pit. The best food grade olive oil is obtained by cold pressing. Olive oil has a delicate, soft taste and pleasant aroma. It is used for preparing dressings and frying some meat, fish and vegetable products.

Cottonseed oil

Cottonseed oil is obtained from the seeds of the cotton plant. For food purposes, this oil must be refined with alkali, since unrefined oil contains a toxic substance - gossiopol.

Refined and deodorized cottonseed oil has a good taste. The color of this oil is straw yellow. In cooking, cottonseed oil is used in the same cases and for the same purposes as sunflower oil.

Soybean oil

Soybean seeds contain 20 to 25% oil, which is extracted from them by extraction or pressing. Due to its good taste, this oil is widely used. Therefore, every year more and more areas are sown with soybeans. The main growing areas of soybeans are the Far East, Ukraine, and the North Caucasus. Soybean oil is used only in refined form and for the same purposes as sunflower or cottonseed oil.

Flaxseed and hemp oil

After refining, linseed oil can be used for food purposes, but in cooking these fats are rarely used, since they have very limited storage stability, quickly thicken and are unsuitable for frying, as they give the fried product a specific “drying oil” flavor.

Mustard oil

Oil is obtained from the seeds of white or blue mustard, which, after careful purification, has a pleasant, mild taste. The color of refined mustard oil is intensely yellow. The specific smell of this oil, which is particularly well suited to some dough products (mustard bread is prepared with mustard oil), does not make it possible to widely use it for other culinary products.

Corn oil

To obtain oil, the germ of corn kernels is pressed or extracted. Refined corn oil is golden yellow in color; it is used in the manufacture of confectionery products.

Peanut butter

The walnut kernel contains up to 58% fat. Cold pressed nut oil has a light yellow color, pleasant taste and smell; it is used in confectionery production.

Peanut butter

This oil is produced from the peanut kernel (groundnut). Refined oil obtained by cold pressing has a good taste and pleasant aroma. It is used as a salad dressing and for frying. Peanut oil is also used in confectionery production.

"Dietary fats"

High-quality native olive oils have the taste and smell of fresh olives; “green smells” can be felt in the oils - grass, freshly cut hay, lettuce leaves and such unusual aromas as chocolate, anise. Depending on the taste characteristics, types of native olive oils are distinguished - from very sweet and mild to bitter and savory.In addition, the general type of oils depends on their place of origin. Native olive oils from Spain are spicy and savory. Native olive oils from Italy have a full range of flavor sensations - from fruity-sweet and nutty with a punchy taste to very savory with a fiery pungency. Native olive oils from Greece are classified as herbal oils. They are characterized by the aroma of freshly cut lawn or hay. The degree of spiciness varies depending on the manufacturer. Native olive oils of France are soft and sweet, with a fruity taste and aroma of apples and peach or lemon and tomatoes, and moderately spicy. The range of native olive oils from California (USA) is represented by almost all types - most often soft and sweet, piquantly spicy.

Cottonseed oil. Raw cottonseed oil has a peculiar color with a brown tint, which determines the presence of gossypol. The composition of cottonseed oil triglycerides is dominated by linoleic (45.0-59.4%), oleic (16.6-26.6%), palmitic (17.9-27.5%) acids. After sunflower oil, cottonseed oil is the most common raw material for the fat processing industry. Cottonseed oil is produced refined (neutralized deodorized and neutralized non-deodorized) and unrefined.

Cotton salad oil is also produced, which is a liquid fraction of pressed refined oil of the highest or 1st grade, isolated by fractionation at a temperature of 8 °C.

For food purposes, only refined oil of the highest, 1st and 2nd grades obtained by pressing is used. Cotton salad oil is produced deodorized for direct consumption and non-deodorized for food production.

Refined deodorized 1st grade should be transparent without sediment, odorless, with the taste of impersonal oil, refined non-deodorized premium, first and second grades - transparent without sediment, taste and smell characteristic of cottonseed oil without foreign odors and tastes.

Linseed oil. The most important components of flaxseed oil are fatty acids - linoleic (up to 20%), linolenic (up to 60%), oleic (20-30%), saturated fatty acids (about 10%). In addition, flaxseed oil contains tocopherol 120 mg per 100 g. For food purposes, only fresh refined bleached oil of the 1st and 2nd grades is used, since under the influence of oxygen, flaxseed oil quickly goes rancid and thickens. When exposed to air in a thin layer, it dries to form a hard elastic film, insoluble in organic solvents, called linoxin.

Soybean oil. The composition of soybean oil triglycerides is dominated by linoleic (52.0-65.0%) and oleic (25.0-36.0%) acids. Crude soybean oil is brown with a greenish tint; after refining it is light yellow. Soybean oil is produced in hydrated grades 1 and 2; refined; refined bleached and unbleached; refined deodorized. First grade hydrated soybean (pressed) is intended for retail chains and public catering establishments; refined unbleached (pressed); refined deodorized. It should be transparent, the taste and smell characteristic of soybean oil, without foreign tastes and odors; in deodorized oil, it should be odorless, the taste of impersonal oil.

Peanut butter. Peanut oil triglycerides are dominated by oleic (51.0-80.0%), linoleic (7.0-26.0%) and palmitic (6.0-11.0%) acids. A special feature of this oil is the presence of arachidic and lignoceric acids. Peanut oil is produced as refined deodorized and non-deodorized, as well as unrefined premium, 1st grade and technical. Refined deodorized oil is used for food. It should be transparent, impersonal in taste and smell, light yellow with a greenish tint. All other types of oil are used in confectionery, baking and margarine production.

Sesame oil. Its composition is dominated by oleic (36.0-48.0%) and linoleic (35.8-55.6%) acids. From the seeds, freed from the shells, after roasting and grinding on millstones, tahini oil is obtained, which is used to make halva. Sesame oil is produced for food purposes in refined and unrefined grades 1 and 2. Refined oil should be transparent, unrefined after settling at a temperature of 20 ° C for 24 hours, transparent above the sediment, the taste and smell characteristic of sesame oil, without foreign smell, taste and bitterness.

Hemp oil. It contains a significant amount of linolenic acid (14.0-28.0%), linoleic (48.0-70.0%) and oleic (6.0-17.0%). First grade pressed refined and unrefined hemp oil is produced for food purposes. Edible hemp oil should be green in color, of varying intensity, taste and smell characteristic of hemp oil, without foreign smell, taste, or bitterness.

Camelina oil is produced from the seeds of the camelina plant. The fatty acid composition is dominated by oleic (9.0-27.0%), linoleic (15.0-45.0%), linolenic (20.0-39.0%) and gondoic (12.0-22. 0%) acid. Depending on the processing method, it is divided into refined and unrefined. Camelina oil should be yellow in color of varying intensity. Currently, the production plant produces refined camelina oil for food purposes according to the developed specifications.

Poppy oil is extracted from the seeds of the oleaginous and opium poppy (poppy seeds are an oil-containing industrial waste). The oil contains oleic (28.0-30.0%) and linoleic (up to 65.0%) acids. Poppy seed oil is light yellow in color, with an unpleasant taste and odor; it is used in the confectionery industry and for technical purposes (after bleaching, the oil becomes almost colorless and can be used to prepare painting paints).

Almond oil is obtained from almond nuts. Almond oil, depending on the processing method and quality indicators, is produced unrefined of the 1st and 2nd grades, hydrated and refined. Refined oil is intended for direct consumption; for food production - refined, hydrated and unrefined 1st grade oil; for technical purposes - unrefined oil of the 2nd grade. The taste and smell of refined and hydrated almond oil is weak, the color is no darker than light brown; unrefined has the smell characteristic of almonds, the color is no darker than dark yellow.

Palm and palm kernel oil. Palm oil contains mainly palmitic (32-45%) and oleic (38-52%) fatty acids.

Modern technology for the production of palm oils includes a series of sequential operations: sterilization of palms, separation of fruits from the palm using special machines, separation of pulp from “nuts” (by various methods, for example in boilers with rotating knives at 95-100 ° C), extraction of oil from pulp by pressing (up to 100 kg/cm2) or centrifugation. The use of centrifuges speeds up extraction and increases oil yield. The resulting raw oil contains pulp particles, sand and up to 20-40% water, so it is settled and purified.

The pericarp pulp contains 22-70% fatty oil (palm oil), obtained by pressing or boiling. Due to the high content of carotenoids, it has an orange-yellow color, a pleasant violet aroma, hardens at room temperature, melts at 27-45 ° C. This oil is used as a technical oil (lubricating oil, for the production of soap and candles), although in West Africa it has been traditionally used for about 5 thousand years in local cuisine, to the dishes of which it gives a characteristic color and aroma.

The kernels contain about 30% palm nut oil. It is almost colorless, has a characteristic nutty taste, like coconut oil, and is one of the best vegetable oils, used mainly for the preparation of margarine and other edible fats; in medicine it is used in ointment and suppository bases.

During storage, crude palm oil easily undergoes hydrolysis and acquires a strong taste.

Currently, palm oil production has reached almost 19% of the total balance of fats and oils potentially suitable for human consumption. The vigorous expansion of production and increased competitiveness of palm oil on the world market was facilitated by the improvement of its quality, as well as the improvement of technologies for collecting raw materials, rapid processing (within 24 hours), storage and transportation of products, and the transition to oil fractionation. The oil and fat complex of Malaysia, in addition to crude palm and palm kernel oils, supplies the world market with 14 oil products based on them: neutralized (hydrated) palm oil, neutralized clarified palm oil, refined clarified deodorized (RBD) or neutralized clarified deodorized (NBD) palm oil, raw palm olein, neutralized palm olein, neutralized clarified palm olein, RBD or NBD palm olein, doubly fractionated palm olein, crude palm stearin, neutralized palm stearin, neutralized clarified palm stearin, RBD or NBD palm stearin, palm oil fatty acids, distilled fatty acids palm oil.

Coconut oil is produced unrefined and refined deodorized. The color of coconut oil (at a temperature of 15 ° C) is white with a yellowish tint, the consistency is soft, and at 40 ° C the oil should be transparent, a slight straw-yellow tint is allowed, the taste and smell characteristic of this type of oil, without any foreign taste or smell and bitterness. The fatty acid composition is dominated by lauric and myristic fatty acids; in addition, it is characterized by a high content of low molecular weight saturated acids and an almost complete absence of phospholipids.

Cocoa butter consists primarily of glycerides of palmitic, stearic and oleic acids. It is obtained mainly by pressing. Cocoa butter is white or light yellow in color and has a specific pleasant taste and smell. At room temperature, cocoa butter is solid, melting point is in the range of 28-36 °C. The content of free fatty acids in terms of oleic acid should not exceed 1.75%, unsaponifiable substances - no more than 0.35%, peroxide value not more than 4 mmol SO / kg, saponification number 192-197 mg KOH / g, iodine value 33 -40 rj2/100 g. The oil is used in confectionery, cosmetics, pharmaceuticals and other industries.

When assessing the quality of vegetable oil by physical and chemical indicators, the most important are: color number, acid number, mass fraction of moisture and volatile substances, mass fraction of phosphorus-containing substances (in terms of stearooleolecithin).

Package . Vegetable oils are poured into consumer and transport containers. Vegetable oil for retail sale with a net weight of 450,500 and 700 g is packaged in glass bottles of types VII, IX, X and XVI; with a net weight of 450-2000 g - in bottles made of painted (or unpainted) polymer materials, approved for use by the State Committee for Sanitary and Epidemiological Supervision; with a net weight of 2000 and 3000 g - in glass jars; in multilayer bags with a capacity of 1000 cm3 made of a combined material (polyethylene, cardboard, foil), approved by the State Committee for Sanitary and Epidemiological Supervision for contact with vegetable oils and ensuring the safety of the oil in the packaging during transportation and storage. In addition, refined deodorized cottonseed oil is poured into flasks and containers; and refined, non-deodorized - into barrels. Peanut edible oil is produced packaged in glass bottles of 250 and 500 ml.

In addition, vegetable oils are poured into transport containers: railway tanks, tank trucks with tightly closing hatches, steel barrels and flasks.

Storage. Oil packaged in bottles is stored in closed, dark rooms at a temperature no higher than 18 °C, mustard oil - no higher than 20 °C. Olive oil is stored in a cool, dark place. When stored at temperatures below 8 ° C, crystallization of olive oil occurs - it becomes thick and cloudy, which is not a defect, since with increasing temperature the oil acquires its previous appearance.

The shelf life of vegetable oils (in months from the date of bottling) in accordance with the current regulatory documentation is: sunflower, packaged in bottles - 4, sunflower, bottled in flasks and barrels - 1.5; rapeseed - 12; refined deodorized corn - 4; olive oils, packaged in bottles - 12; refined deodorized cotton - 3; refined non-deodorized - 6; refined deodorized peanuts - 6: soybean, bottled, refined deodorized - 1.5; refined unbleached (pressed) and hydrated first grade (pressed) - 3; refined deodorized bottled into flasks and barrels - 1; refined unbleached (pressed) and hydrated first grade (pressed) - 3; refined deodorized mustard - 3; refined, non-deodorized, hydrated and unrefined - 6; refined hemp - 2; unrefined - 4.

Source: znaytovar.ru

Animal fats

The type of animal, its age, fatness, feed, place of deposition and depth of fat in the carcass are all factors that influence the chemical composition and properties of animal fats, increasing or decreasing the nutritional value of the product and determining its most correct and appropriate use for culinary purposes. .

Animal fats widely used in cooking include beef, lamb and lard. It is also impossible to ignore such a high-quality product as poultry fat (goose, duck, chicken).

Lamb fat

Lamb fat is one of the hardest and most refractory animal fats. Depending on the age of the animal and the location of fat deposition, the melting point of lamb fat ranges from 44 to 51°.

Beef fat

Beef fat is more fusible and soft (melts at a temperature of 42-49°) and, finally,

Pork fat

Pork fat, the softest in consistency (melts at 33-40°).

For rendering fat, raw lard is used, i.e., fatty tissue removed from the outer or inner parts of the carcasses of cattle, pigs and sheep. Raw beef lard, intended for rendering fat of the highest grades, is removed from carcasses of fatty, above-average and medium fatness, and for these grades only lard from fresh, not frozen carcasses is used. Depending on the age of the animal and the location of deposition, raw beef lard has a white or light yellow color.

Lard removed from the digestive organs is grayish in color and, unlike external and internal fat, sometimes has a specific odor. To prepare the highest grades of lard, fatty tissue is used, removed from the internal and partly external parts of pork carcasses of greasy, semi-greasy and meat fatness. Extra-grade lard is prepared from fresh, selected, mainly perinephric fat.

Fats in the human diet are the main source of energy. When 1 g of fat is oxidized in the body, 37.7 kJ of energy is released, i.e., almost 2.5 times more than when 1 g of proteins or carbohydrates is absorbed (oxidized). With the exception of castor oil, tung oil and some other few types, mainly obtained from tropical plants, all natural fats can be used in food.

The average fat intake for a person is about 100 g per day, including fats found in all foods. However, this norm may vary depending on the person’s age, physical activity and some other factors.

Fats not only have a high calorific value; they are of great physiological importance, since they are suppliers of substances necessary for the human body - vitamins, essential fatty acids, phosphatides.

In terms of their chemical composition, fats are mixtures of various triglycerides. The triglyceride molecule is an ester formed by the trihydric alcohol glycerol and three molecules of fatty acids. The composition of natural fats consists mainly of monobasic, saturated and unsaturated fatty acids containing one acid group (COOH). They are characterized by an unbranched carbon chain and an even number of carbon atoms in the molecule. Acids with an odd number of carbon atoms are found in some fats in small quantities.

Depending on the number of carbon atoms, low molecular weight saturated fatty acids are distinguished, containing from 4 to 10 carbon atoms. These include oil, nylon, caprylic, capric. These acids, with the exception of capric acid, are liquid at room temperature and give the fat its characteristic smell and taste. They are found in milk and lamb fats, as well as in some solid vegetable oils.

The most common high molecular weight saturated fatty acids found in natural fats are lauric, myristic, palmitic and stearic. These acids have a high melting point and are found in large quantities in solid vegetable and animal fats.

Among the unsaturated (unsaturated) high-molecular fatty acids, the most common are acids containing 18 carbon atoms: oleic, linoleic, linolenic. At room temperature, unsaturated acids are liquid. Fats containing predominantly unsaturated and low molecular weight acids have a liquid or paste-like consistency and are better absorbed by the body. Polyunsaturated acids have increased reactivity and are easily oxidized by atmospheric oxygen. One of the properties of unsaturated acids is their ability, in the presence of catalysts (nickel, copper, etc.), to add hydrogen at the site of double bonds. As a result of this reaction, unsaturated acids are reduced to saturated acids and the fat acquires a solid consistency.

Polyunsaturated fatty acids are of particular importance for the human body: linoleic, linolenic and arachidonic. Linoleic acid (two double bonds) is isolated as the main one, the body's need for which is 3-5 g per day. Linoleic acid is found in vegetable oils - corn, cottonseed, soybean; its content in sunflower oil reaches 60%.

Properties of fats

Are common to most of them. The density of fats is less than the density of water (890-980 kg/m3). Fats are insoluble in water, but dissolve well in organic solvents (ether, gasoline, chloroform, dichloroethane, etc.). This property underlies the extraction of fat with solvents from oilseed raw materials (extraction).

When heated to high temperatures (260-300°C), fats decompose to form volatile products with an unpleasant odor. Prolonged heating at lower temperatures of liquid vegetable oils containing polyunsaturated fatty acids leads to their thickening and loss of nutritional qualities.

When interacting with water, complete breakdown of triglycerides can occur, i.e. hydrolysis of fat, with the formation of glycerol and free fatty acids as breakdown products. Hydrolysis is accelerated by improper storage of raw materials and fats, high humidity and temperature, and by creating conditions favorable for the action of lipolytic enzymes (lipases). Increasing the free fatty acid content of dietary fats is undesirable as it may lead to loss of nutritional value.

Fats can be oxidized by atmospheric oxygen. In this case, various compounds are formed: peroxides and hydroperoxides, hydroxy acids, low molecular weight acids, aldehydes. The buildup of these foods can cause the fat to spoil, which can taste rancid or greasy. Oxidation processes are accelerated by exposure to light and increased temperature. Triglycerides, which contain acids containing three or more double bonds, are easily oxidized by molecular oxygen. Some fats contain substances that slow down oxidation (antioxidants). Natural antioxidants of fats are carotenes and tocopherols (vitamin E). When storing fats, factors that accelerate the processes of hydrolysis and oxidation of fat should be eliminated as much as possible.

Fats contain accompanying substances: phosphatides, pigments, vitamins, sterols, waxes, free fatty acids, etc. The highest content of these substances is typical for vegetable oils; for example, in unrefined soybean oil the content of phosphatides can be up to 3.5%; in large quantities they form sediment in the oil and worsen its appearance.

The common pigments for most fats are carftinoids. They give fats a light yellow to orange color. Chlorophylls, which give fats a greenish color, are found in some vegetable oils (linseed, hemp). Cottonseed oil contains gossypol, a pigment that has toxic properties and gives the oil a dark brown color. Vitamins of groups A, D, E, K are fat-soluble (see p. 15).

Waxes can make the oil appear cloudy. By structure, they are esters of high molecular weight monohydric alcohols and high molecular weight saturated fatty acids. Waxes have no nutritional value, as they are not absorbed by the human body.

Free fatty acids in fats are considered to be products of incomplete synthesis or breakdown of triglycerides. An indicator of the quantitative content of free fatty acids is the acid number of fat, which is expressed by the number of milligrams of potassium hydroxide required to neutralize the free fatty acids contained in 1 g of fat. An increased acid number indicates spoilage of fat.

Classification of fats

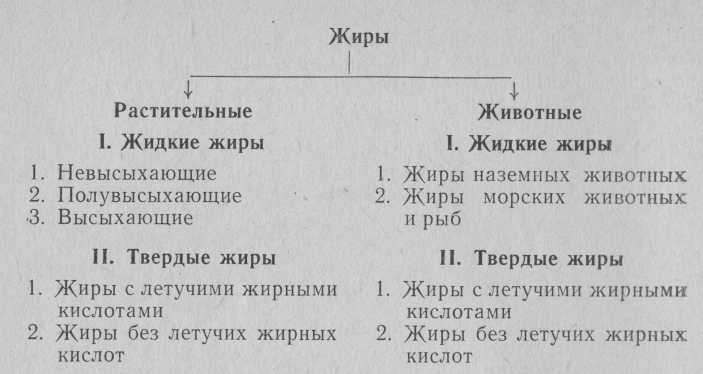

Fats are classified depending on the raw material into animal and vegetable . Based on consistency, they are divided into solid and liquid . Solid fats, in turn, are divided into those containing low molecular weight acids (coconut oil, milk and lamb fats) and those not containing low molecular weight acids (cocoa butter, animal fats - pork, beef, bone).

Separately, fats are distinguished, which include various types of natural and processed fats. These include margarines, cooking, confectionery and baking fats.

Liquid vegetable oils are divided into several groups according to their fatty acid composition and ability to dry (form a film on the surface of the oil). Oils like tung (dry quickly), form strong films on the surface and contain a large amount of acids with three conjugated double bonds. Oils like flaxseed (drying out) - flaxseed, hemp - contain about 50% linolenic acid. Oils similar to poppyseed (semi-drying) - poppy, sunflower, soybean, corn, cottonseed and some others - are characterized by a high content of linoleic acid. Oils like olive oil - olive, almond and peanut - do not dry out in air in a thin layer and contain oleic acid as the main one. Castor oil does not dry out in air; it contains unsaturated ricinoleic hydroxy acid.

Fat processing

The technological process of processing animal fats consists of the following operations: cooling, washing with cold water, grinding adipose tissue and melting fat.

Salot heating can be carried out using dry and wet methods. With the dry rendering method, raw lard is loaded into a lard boiler that has double walls. After burning the raw material for rendering fat, it is produced with steam or hot water.

With the wet rendering method, raw lard is poured into a boiler with water and in this form is heated with steam. With this method of rendering, the adipose tissue releases the greatest amount of fat; however, along with fat, nitrogenous substances also enter the broth, which reduce the stability of fat during storage. The best results are obtained by dry lard heating in double-walled boilers heated by water or steam. This method of rendering lard protects the greaves - the fabric remaining after rendering fat - from burning and ensures very good quality of the finished product.

Beef fat

To obtain high-quality beef lard, extra fat extraction is carried out in two stages. The fat obtained after the first rendering is called the first juice. By separating the part, extra grade beef fat is obtained. Extra beef fat is used in cooking for frying meat products. This high-quality fat has a low melting point (not higher than 320). The fat has a pleasant taste and smell. https://depils.com Due to its good taste, it is also used in other hot dishes and is used for frying foods in large amounts of fat (deep frying).

Premium beef fat is prepared from selected, fresh, raw lard. The color of the fat is light yellow or yellow. The consistency at room temperature is solid; when melted, this fat is transparent. The taste of premium beef fat should be pure, without any foreign taste or smell.

Beef fat of the 1st grade is rendered from internal raw lard. In color and consistency, it differs little from premium fat, but this product may have a slight aftertaste of crispy greaves.

Beef fat of the 2nd grade is prepared from benign raw lard. For produce in this class the standard allows for a slightly grayish or pale green hue and a roasted greave odour. When melted, grade 2 beef fat may not be clear enough.

Lamb fat

This fat is available in three grades. The highest grade lamb fat is rendered from selected fresh raw fat from the inner and tail parts of the carcass. The color of the finished product is white or pale yellow; The consistency is solid; when melted, the fat is transparent. The taste and smell of this fat are specific to the inherent taste of lamb.

Lamb fat of the 1st and 4th grades is prepared from benign raw lard. These products are characterized by a slightly grayish or greenish tint and the taste of crispy greaves. 2nd grade fat may be slightly cloudy when melted.

Pork fat

This fat is available in four grades. Extra pork fat is prepared from selected perinephric fat from pork carcasses. In terms of its culinary qualities, taste, smell and nutritional value, this fat is deservedly considered the best of all animal fats (except butter). All varieties of pork fat, especially extra, are widely used in cooking for a wide variety of dishes and dough products.

Extra grade pork fat has a white color, a soft and delicate taste, with a slightly pleasant sweetish taste and a barely noticeable delicate odor. At room temperature, pork fat has an extra spreadable consistency. When melted, pork fat is extra transparent.

Pork fat of the highest quality is rendered from fresh, selected raw lard, removed from the inside of the carcass. In terms of smell, color, taste and consistency, it differs little from extra fat.

Pork fat of the 1st and 2nd grades is rendered from benign raw lard. 1st grade fat is made from internal lard, and for 2nd grade all types of fresh raw lard are used. The color of the fat is white with a slight yellowish tint; consistency is thick or pasty. In the melted state, 1st grade fat is transparent, 2nd grade fat may be cloudy. Both varieties have the smell of crispy greaves.

Poultry fat

The fat of geese, turkeys, ducks, and chickens is an excellent product. It is easily digestible, melts at low temperatures (goose fat, for example, at 35-37°); its smell and taste are pleasant. This fat is good for preparing many dishes and snacks, especially from the meat of these birds. The ability to accumulate fat in geese is especially great; fattened specimens of this bird can contain up to 46% fat. First-class turkeys, ducks, and chickens have a lot of fat.

Catering establishments must skim and render excess fat from fatty poultry entering the cooking process. This fat must be taken into account separately and used carefully in accordance with its culinary purpose.

Margarine

Margarine is produced in factories equipped with the latest technology, under the most careful laboratory and technochemical control. This is such a benign and complete product that doctors consider it possible to use margarine for some types of dietary foods. The main raw materials for the production of margarine are various vegetable and animal fats. Of the animal fats, whale oil is the most widely used.

Among vegetable oils, the industry uses mainly sunflower, cottonseed and soybean oils for the production of margarine.

Vegetable oils and marine animal fats for the production of margarine are subjected to a process of hydrogenation (that is, they are transferred from a liquid to a solid state) and deodorization. Hydrogenation of fats provides the finished product with the necessary consistency, and deodorization eliminates the specific taste and odor inherent in marine animal fats and some vegetable oils.

Depending on the source raw material, methods of its processing, culinary purpose and taste, margarine is divided into table and kitchen margarine. When using both table and kitchen margarines, the cook must take into account the taste characteristics of various types of margarine and their taste compliance with the prepared food. https://depils.com For those dishes, snacks, dough products whose taste corresponds to butter, only table grades of margarine can be used.

Combined kitchen margarines, especially pork fat, can be used in all dishes that match the taste and aroma of animal fats, in hot dishes made from meat products and in some flour products, as well as in meat and vegetable minced meats and fillings.

All types of kitchen margarines are suitable for frying in large quantities of fat (deep fat), and especially hydro-fat, which has a high smoke point (233°) and even when heated very strongly does not impart a bitter taste or smell of smoke to the fried product.

Fats used in the food and confectionery industry.

Fats are widely distributed in nature. By their chemical nature, fats are mixtures of glycerol esters (triglycerides); the glycerol in them is esterified with fatty acids.

All the diversity in the properties of fats depends on the chemical composition of fatty acids and their location in the triglyceride molecule that makes up the fat. In general, triglycerides have the formula:

where R1, R2 and Rз are fatty acid residues.

Triglycerides include saturated (saturated) and unsaturated (unsaturated) fatty acids. Unsaturated fatty acids are present in liquid vegetable oils in greater quantities than in solid fats.

Fats extracted from plant and animal tissues are usually not homogeneous and chemically pure substances. They are a mixture of a very complex composition, in which the predominant amount of fat is present. Fat contains a large number of impurities - waxes, sterols, lipoids, pigments, resins, mucous and protein substances, etc.

Based on their origin, fats are divided into two main groups: vegetable and animal. Both of these groups, depending on the content of solid glycerides in them, are in turn divided into liquid and solid. Liquid and solid fats, depending on their composition and properties, are also divided into subgroups. The classification of fats can be presented in the following diagram:

A wide variety of fats are used in the confectionery industry. Some of them are an integral part of the raw materials used, others in the form of commercial varieties are added to the recipes of various confectionery products. In the second case, mainly solid natural vegetable fats and artificially hardened (hydrogenated) vegetable fats are used. Butter is used from animal fats.” Liquid vegetable oils are used in small quantities, mainly as auxiliary materials (lubricant, component of gloss for coating, etc.).

To assess the quality of fat, its inherent physical and chemical properties and its constants are determined. The most characteristic constants of fat include: specific gravity and melting and pour point, which characterize the ratio of liquid and solid acids in the composition of fat; iodine number, which is a measure of the amount of unsaturated acids that make up fat triglycerides; saponification number, which characterizes the fatty acids that make up a given fat by molecular weight; acid number indicating the degree of fat breakdown.

Liquid vegetable oils

Vegetable oils are extracted from oil-bearing plants in two ways: pressing and extraction. A combined method is also known, in which it is first pressed and then extracted.

Regardless of the method of obtaining oil, the seeds are cleaned, dried, separated from the shell, ground and fried. After separating the shell, the kernel is crushed on rolling mills, steamed and dried in a roasting pan. The pulp coming out of the fryer at a temperature of 105-110 ° C enters the press, where the oil is squeezed out. The resulting cake contains an average of 6-8% fat.

Despite the high pressure used during pressing, it is not possible to extract all the oil from the cake even with repeated pressing. The extraction method makes it possible to extract almost all the oil from the seeds. Gasoline is mainly used as an extracting agent - its fractions with a certain boiling point. The solid residue obtained after extraction and called meal contains 1-1.5% fat. Oil obtained by extraction and intended for food purposes is subjected to refining to remove mechanical impurities, free fatty acids and mainly from solvent.

The USSR produces the most sunflower and cottonseed oil. In table 12 shows the physicochemical parameters of these oils.

Table 12 Physico-chemical parameters of sunflower and cottonseed oil

| Indicators | Sunflower oil | Cotton oil |

| Specific gravity at 15°C | 0,921—0,931 | 0,925—0,932 |

| Pour point in °C…. | From—16 | 0 to 6 |

| up to—18.5 | ||

| Saponification number | 185—194 | 191—199 |

| Iodine number | 119—144 | 101—120 |

Solid vegetable oils

Solid vegetable oils processed in the confectionery industry include cocoa butter, a solid fat that does not contain glycerides of volatile fatty acids, and coconut butter, which contains a significant amount of volatile fatty acids.

Cacao butter. This oil is obtained in confectionery factories from cocoa beans, which contain up to 58%. Cocoa butter is a valuable raw material in the confectionery industry. It is used in the production of chocolate, chocolate glaze, candy bodies, and the best types of chocolate fillings for caramel.

The chemical composition of cocoa butter is mainly a mixture of glycerides of fatty acids - stearic, palmitic and oleic. When fresh, it has a yellowish color, pleasant taste and aroma. At room temperature (20° C), cocoa butter has a hard and brittle structure, without signs of a spreadable consistency.

The melting point of cocoa butter is lower than the human body temperature (32-36°C), so confectionery products containing cocoa butter easily melt in the mouth without leaving a greasy aftertaste.

When cocoa butter is cooled to a temperature below 20 ° C and kept for a long time at a temperature below the pour point, it hardens, acquiring a crystalline structure and decreasing in volume. This property of butter is valuable in chocolate production, since reducing the volume of butter contained in the chocolate makes it easier to knock out the chocolate from the molds.

Cocoa butter has the property, upon crystallization, to form various crystalline forms that have different physicochemical properties. This property is called polymorphism.

There are 4 polymorphic forms in cocoa butter - ˠ, α, β', β; three of them are unstable (metastable), and the fourth is stable and retains its state for a long time (β-form).

The transformation of unstable phases into stable ones is accompanied by a violation of the homogeneity of cocoa butter. The polymorphism of cocoa butter explains the defect observed in chocolate - graying.

A valuable property of cocoa butter is its ability to be preserved for a long time without noticeable signs of spoilage and rancidity.

Physico-chemical parameters of cocoa butter

| Specific gravity at 40°C | 0,9206 |

| Melting point in °C | 32—36 |

| Pour point in °C | 22—27 |

| Saponification number | 192—200 |

| Iodine number. | 34—36 |

| Acid number | 1,0—1,5 |

Coconut oil . Coconut oil has a consistency similar to ghee at room temperature. It is obtained from the fruits of the coconut palm. The pulp is extracted from the split fruit and dried. The dried pulp is called copra. Copra oil is obtained by hot pressing. When fresh copra is processed, the oil obtained has a good taste.

In the confectionery industry, coconut oil is used in the manufacture of many types of candies, caramel fillings (butter-sugar) and waffle fillings.

Physico-chemical parameters of coconut oil (refined edible)

| Specific gravity at 15°C | 0,925—0,938 |

| Melting point in °C | 23—29 |

| Saponification number | 254,0—266,0 |

| Iodine number | 8,0—12,0 |

| Acid number no more | 0,56 |

| Refraction at 40°C | 33,0—36,3 |

According to the standard, coconut oil is divided into refined edible and unrefined technical. According to the standard, coconut oil should be white at a temperature of 15-20°C, and transparent at 40°C. Edible refined oil should be without bitterness.

Butter

This butter is obtained by churning milk or cream. In terms of composition, it does not represent a homogeneous product. It consists of the same substances that are part of milk.

The average composition of butter (in%): fat 83, protein 1.1, lactose 0.5, minerals 0.2, water 15.2.

Depending on the type of raw materials and production method, butter is divided into the following types: sweet cream from raw or pasteurized cream, Vologda, sour cream, cheese. The best butter comes from pasteurized ripened cream. Cream for sweet butter is pasteurized at 85-87°C, and for Vologda at 93-98°C (instant pasteurization). The high temperature of cream pasteurization during the production of Vologda butter gives it a special taste (nutty).

In the production of cultured butter, the cream is pasteurized at 85-90° C and then fermented with a pure culture of lactic acid bacteria.

Cheese butter is produced from cream isolated from whey, which is obtained during cheese making. Cheese oil contains a large amount of proteins, so it is easily spoiled.

Butter can be sweet or salty. Salty has a denser structure and is better preserved; it contains 1-2% table salt.

Each type of oil, depending on its quality, is produced in several grades: extra, highest, I and II.

In the confectionery industry, butter is used to produce various creams, some types of sweets, toffee, butter cookies and cakes.

Hydrogenated fats (salomas)

Hydrogenated fats are artificially hardened liquid fats of vegetable or animal origin.

The difference in the chemical composition of solid and liquid fats is that saturated acids predominate in solid fats, while unsaturated acids predominate in liquid fats. The curing process is where the unsaturated fatty acids contained in the liquid fat are saturated with hydrogen. This saturation with hydrogen (hydrogenation) is carried out in the presence of a catalyst at elevated temperature. It proceeds according to the following scheme:

CnH2n—1COOH + H2 ^ CnH2n+1COOH.

As a catalyst, factories in the USSR use freshly reduced nickel catalyst in a finely crushed state.

By changing the hydrogenation conditions (temperature, duration, etc.), they achieve varying degrees of saturation of the unsaturated acids contained in the fat and thereby regulate the properties of the resulting hydrogenated fat. Fat can be obtained in different consistencies, with different melting points, etc.

Edible hydrogenated fats are used in large quantities in the production of margarine. In the confectionery industry, they are used as small additives in the production of candy bodies, fillings and flour confectionery products.

Margarine

Margarine is an artificially prepared fatty food product, similar in appearance and structure to butter.

The main raw materials for the production of margarine are natural and hydrogenated fats of animal and vegetable origin. From natural animal fats, fats from terrestrial animals are used (oleostok, oleo-oil, lard). Marine animal fats are used only in hydrogenated form. The main types of vegetable oils used in the production of margarine in the USSR are sunflower and cottonseed. Refined soybean oil is also a good product for the production of margarine. Natural and hydrogenated animal fats give the finished margarine the necessary plasticity, so their presence in margarine is very desirable.

To bring the organoleptic properties of margarine closer to natural butter, skim milk is added to the recipe mixture when making margarine.

Margarine is an emulsion. Emulsifiers are used to bring the components of margarine (fat and milk) into an emulsion state. Lecithin preparations and phosphatides are used as emulsifiers.

In terms of nutritional value, margarine differs little from butter, but it does not contain vitamins. Currently, fortified varieties of margarine are being produced.

Depending on the type of raw materials used, margarine is divided into the following varieties: table milk margarine, cream margarine, dairy-free margarine, confectionery margarine - cream and milk. In addition, margarine is produced with the addition of cocoa powder and coffee extract.

The composition of margarines is characterized by the data given in table. 13.

Table 13 Physico-chemical parameters of margarine

| Margarine | |||||

| Indicators | confectionery | ||||

| table milk | withoutmo local | if eternal | slivoch ny | milk ny | |

| Fat in%, not less | 82,0 | 82,5 | 82,0 | 82,0 | 82,0 |

| Moisture in%, no more | 16,5 | 16,5 | 17,0 | 17,0 | 17,0 |

| Salt in%, no more | 0,2—0,7 | 0,2-0,7 | — | — | — |

| Melting point of fat isolated from margarine in °C, not higher | 27—33 | 27—33 | 27—32 | 31 | 32—34 |

| Benzoic acid in%, no more. | 0,07 | 0,07 | 0,07 | — | 0,07 |

Margarine is packaged in wooden or plywood boxes, cardboard boxes or barrels.

Compound fats

Compound fat, or cooking fat, is a mixture of animal and vegetable fats. Animal fats include lamb, beef, pork, bone and hydro fats; from vegetable liquid oils - sunflower, cottonseed, soybean, etc. Compound fats are produced under various names depending on the raw materials used and the purpose of the fat. In the confectionery industry, compound fats have limited use due to their lack of good taste. They are used in small quantities in the production of biscuits.

Confectionery fat

Confectionery fat is prepared specifically for use in the manufacture of certain types of confectionery products. It is refined and deodorized hydrogenated edible vegetable fats with or without the addition of animal fats, vegetable oils and other components. Confectionery fat has an increased hardness compared to ordinary hydrofat and a melting point of up to 37 ° C. It is used in the form of small additives in chocolate and candies, and fat glaze for candies is prepared on its basis. It is recommended to add it to biscuits. According to the latest data, the best quality cookies are obtained by using whole hydrogenated cottonseed oil, which has a melting point of 36-37 ° C, or an anhydrous three-component mixture consisting of 30% pork and beef fat in equal quantities and 70% hydrogenated whale oil or cottonseed oil. The melting point of such a mixture should be 37° C.

Confectionery fat is divided into two groups: fat for chocolate products and candies and fat for wafer and refreshing fillings.

Confectionery fat for chocolate products is a refined, deodorized edible lard made from peanut or cottonseed oil. According to the RTU, it must have a melting point of 32-36.5 ° C, a pour point of 29 ° C, contain at least 99.7% fat, have a moisture content of no more than 0.3% and an acidity of no more than 0.4%.

Confectionery fat for waffle and cooling fillings is a mixture of refined, deodorized edible vegetable lard and coconut oil. According to the RTU, there should be at least 40% coconut oil in the mixture. The melting point of this fat according to the RTU should be 30-32 ° C; pour point not less than 21° C; acidity no more than 0.5°. The fat content and moisture content are the same as fat for chocolate products.

New types of fats for the confectionery industry

As a substitute for cocoa butter, they plan to produce a new fat, similar in composition and properties to cocoa butter. The raw material for the production of such fat is beef fat.

Beef fat is hydrogenated to a melting point of 52-53 ° C, dissolved in gasoline and a low-melting fraction is separated from the solution.

The fat obtained in this way has the following indicators: melting point 35-36 ° C; pour point; 28-29° C; iodine number 37-39; saponification number 190-195.

The new fat can be used in whole or in part as a substitute for cocoa butter in the production of chocolate glaze, chocolate bars, candy bodies, and caramel fillings.

To date, the issue of developing a cocoa butter substitute in the USSR has not been finally resolved. The quality of the resulting fat does not fully satisfy the industry.

In recent years, cotton palmitine has begun to be supplied to confectionery factories as a substitute for coconut oil.

The raw material for the production of cotton palmitine is cottonseed oil, subjected to demargarinization. The isolated solid fraction is hydrogenated. Cotton palmitine can be used in the production of sweets, caramel fillings such as soft drinks, and fillings for waffles.

Spoilage of fats and conditions for their storage